Would it surprise you the best way to increase productivity on the jobsite is through planning and good communication? According to FMi most projects could see up to a 33% increase in productivity through better planning, collaboration, and communication. They go on to say as little as a 10% increase in productivity could double the profit for trades. I can unequivocally say that poor planning and communication kills productivity. I have seen it on my own projects and work hard to prevent it.

How often do these items impact your workers?

- Waiting on materials or tools to arrive?

- Waiting on your GC/CM to provide clarity and remove roadblocks?

- Driving to the supply warehouse every day due to lack of planning?

- Taking a jobsite safari to find misplaced materials?

- Delivering material and moving it multiple times?

Some of these I can help you with and others require you, as the trade contractor, to be organized and communicate with your field staff. Make sure your foreman has time to plan their work and organize material orders to keep your workers moving. Take ownership of your materials on site and track what you have and where it is placed. Work with your GC/CM for a dedicated location to store your products that eliminates moving it multiple times.

I strive to do better and push my teams to do better. My first task every day is to make sure my teams have what they need to keep working.

It takes a lot of work to organize projects but once you have a good system in place it becomes routine and you recognize benefits across the jobsite. These are some of the things we do to keep you organized and provide good communication on the jobsite.

- Daily Huddles – quick 15 minute check-ins first thing every morning.

- Weekly Foreman Mtg – Focused on longer term planning, logistics, and procurement.

- Weekly 1-on-1’s with key trades – A more detailed check in with Project Managers.

- Weekly procurement meeting – Review the log and focus on upcoming critical work..

- Pull Session schedule planning.

- Weekly design check-in – Review status on design updates, RFI’s, Submittals, etc..

- Bi-Weekly OAC – What do we need from the client?

- Weekly team meeting – Status updates and looking for gaps.

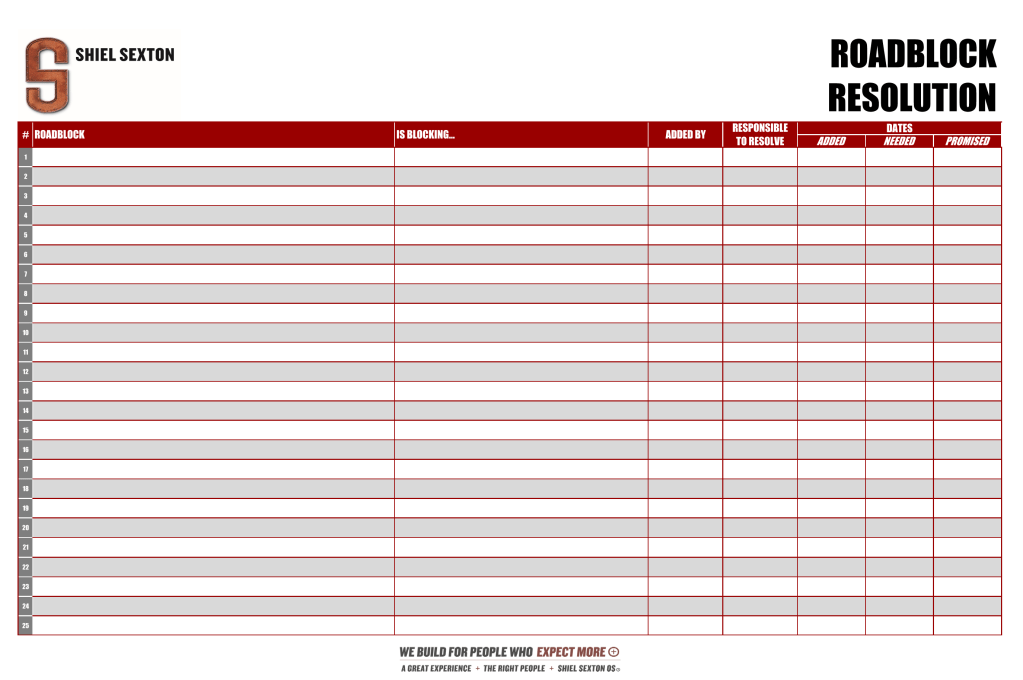

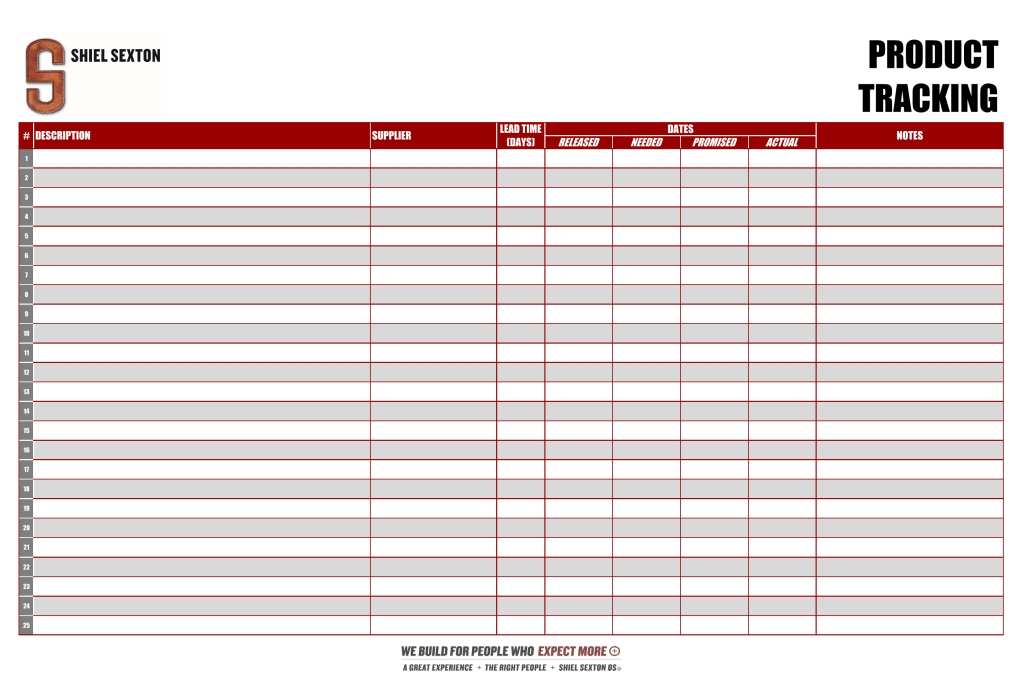

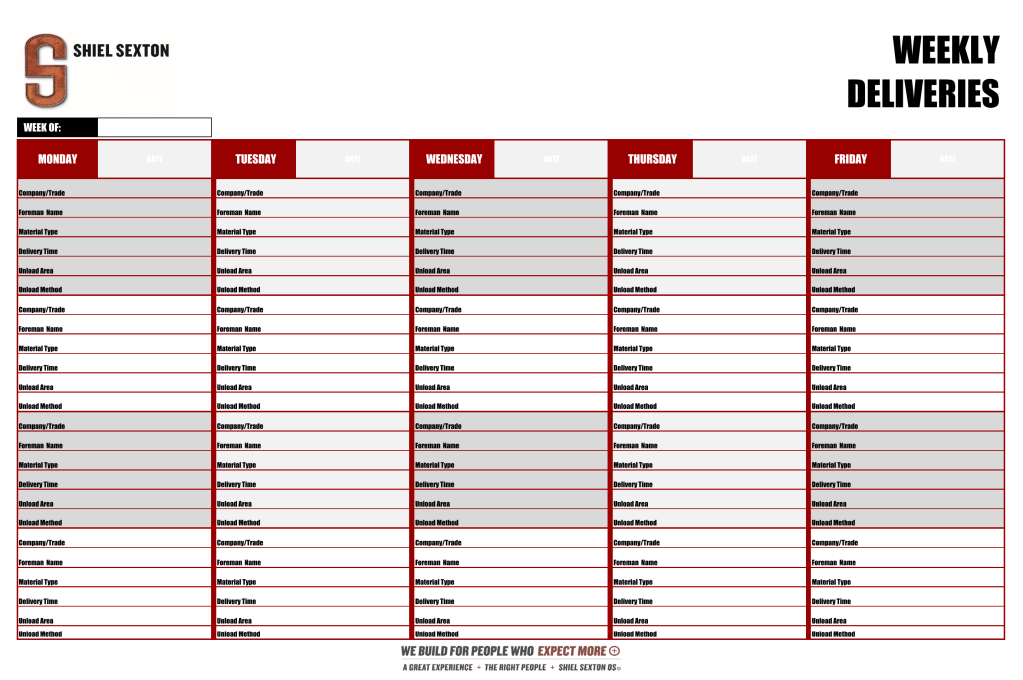

We also like to communicate with large visuals in the trailer and on the jobsite. Keeping all the issues and roadblocks in an excel sheet is great for detailed tracking but is easy to ignore. It is hard to ignore roadblocks on a large 32″x48″ white board on your trailer wall. These are some of the visuals we have in the trailer and trades are welcome to walk in, review, and add items to the list.

Roadblock removal board – Large dry erase board to track critical roadblocks.

Critical Product Tracking board – large dry erase board to track near term critical materials/equipment

Weekly Deliveries Board

I will close with – keep it clean! A clean jobsite is safer and promotes better productivity. It is your responsibility to clean up after your work. Respect the jobsite and the trades coming in to work after you. This is one of my past projects. The superintendent set an amazing standard and the trades respected the work areas and kept it clean. It looked like this across the entire job. Every job should look like this!